Many engineers and technicians encounter puzzling issues with Automotive PCB Rel...

Read More

Thermal stress is a frequent concern when designers and technicians discuss PCB ...

Read More

Automotive PCB Relay issues can lead to unexpected system resets, performance dr...

Read More

In many electrical and industrial applications, a DC overload relay or DC power ...

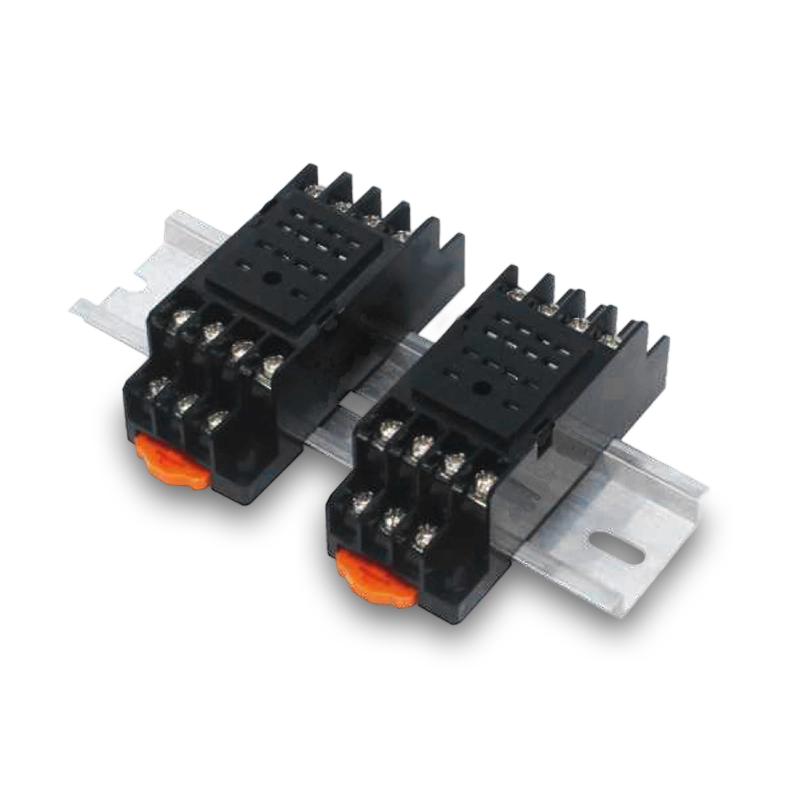

Read MoreIndustrial Control Relays are essential components for managing electrical circuits in industrial environments. Designed to handle a wide range of voltage and current levels, these relays allow operators to control multiple devices through a single input signal. By isolating control circuits from power circuits, Industrial Control Relays ensure both operator safety and system reliability. They are widely used in motor control panels, lighting systems, pumps, and machine operation circuits, offering dependable performance even under demanding industrial conditions.

One key advantage of Industrial Control Relays is their ability to provide precise and stable switching. With robust contacts and effective coil insulation, these relays maintain performance under fluctuating voltage and current loads. Engineers often rely on them to simplify wiring layouts, reduce the risk of electrical faults, and provide protection for sensitive equipment. Industrial Control Relays also play an important role in emergency shutdown and fault detection systems, enabling automated responses when abnormal conditions occur. Their versatility allows integration into various industrial applications, from manufacturing machinery to processing equipment, where consistent and reliable operation is a priority.

In addition to reliability, Industrial Control Relays are designed for longevity. Components are selected to resist mechanical wear, vibration, and temperature bads. Maintenance is straightforward, and replacements can be carried out without affecting other parts of the system. By offering stable operation and flexible control options, Industrial Control Relays help maintain efficient workflow and reduce downtime across industrial settings.

Industrial Automation Relays serve as a critical interface between sensors, controllers, and actuators, providing reliable electrical switching in automated systems. These relays enable precise timing, sequencing, and control of machinery, supporting applications such as conveyor systems, robotic arms, automated assembly lines, and packaging equipment. By responding rapidly to control signals, Industrial Automation Relays reduce delays and ensure smooth operations, contributing to improved production efficiency and consistency.

These relays are designed with compact housings, allowing integration into control panels and automation equipment without occupying excessive space. They often include features such as LED status indicators for easy monitoring, coil protection for long-term reliability, and standardized terminals for easy wiring. Industrial Automation Relays also provide the ability to handle frequent switching cycles, making them suitable for high-speed production environments where performance cannot be compromised.

The application of Industrial Automation Relays extends beyond production lines. They are used in process control systems, environmental monitoring equipment, and energy management solutions to automate routine operations and reduce human intervention. Their flexibility allows adaptation to various industrial automation standards and system configurations. With reliable performance, Industrial Automation Relays help factories achieve operational efficiency while ensuring that automated processes run smoothly under different load conditions and environmental factors.

Industrial Relays offer versatile and dependable solutions for a wide range of electrical control requirements in industrial settings. They are used to switch electrical circuits, control power distribution, manage heavy machinery, and integrate with safety and monitoring systems. These relays are available in multiple types, including electromechanical, solid-state, and hybrid designs, providing engineers with choices suited to load capacity, switching frequency, and environmental conditions.

Common applications of Industrial Relays include manufacturing plants, power distribution systems, process control equipment, and transportation machinery. They are valued for their consistent performance under repeated switching operations, resistance to vibration, and tolerance to humidity and electrical interference. Industrial Relays also contribute to extending equipment lifespan and reducing maintenance frequency, which is critical for maintaining operational continuity.

Beyond their primary switching function, Industrial Relays can be incorporated into intelligent control networks, providing real-time feedback on system status and supporting remote monitoring. They enhance operational safety by preventing electrical overloads and enabling controlled shutdowns during fault conditions. With robust construction and reliable performance, Industrial Relays offer industrial operators the flexibility to adapt systems for evolving production needs while maintaining stable operation across various applications. Their role in modern industrial environments is essential for ensuring efficiency, safety, and reliable control over complex electrical systems.