When selecting the right Power Relay for your application, you may encounter two primary types: mechanical relays and solid-state relays. Each has distinct features, benefits, and drawbacks, depending on the specific needs of your system. Understanding these differences is crucial for ensuring that you choose the right relay that meets the requirements of your industrial or automation environment.

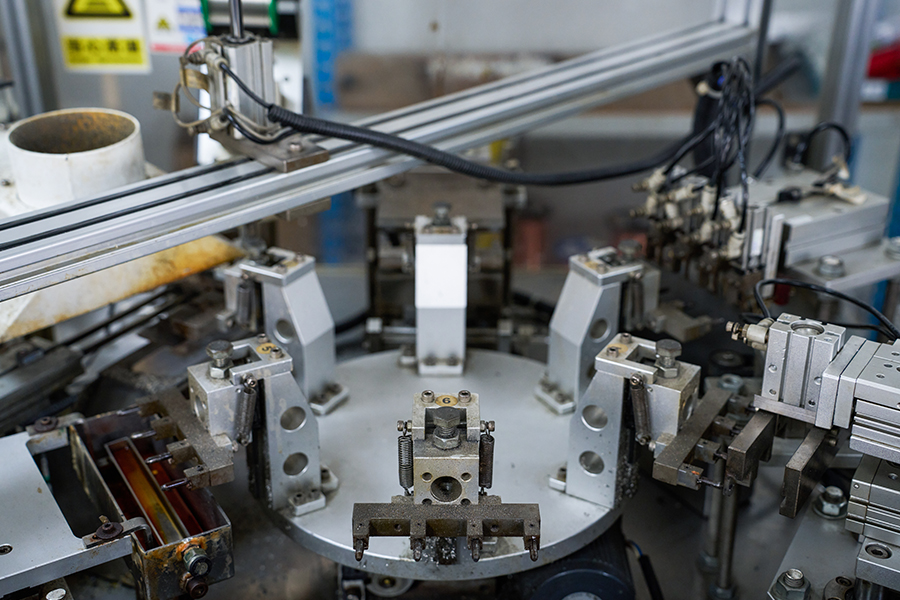

At Wenzhou Jiajie Electric Co., Ltd., our Relay Factory specializes in producing robust mechanical relays that are designed to withstand heavy-duty applications. With over 15 years of experience in relay manufacturing, we understand the demands of industrial systems and offer mechanical relays that are engineered for long-lasting performance.

What Is a Mechanical Relay?

A mechanical relay is a traditional relay design that uses moving parts to open and close electrical contacts. These relays are widely used in industrial environments because they are simple to design and operate. The main advantage of mechanical relays is their ability to handle high voltages and currents.

What Is a Solid-State Relay?

A Solid-State Relay (SSR) operates using semiconductor components instead of mechanical contacts. These relays do not have moving parts, which eliminates the mechanical wear and tear associated with traditional mechanical relays. This makes them ideal for applications where reliability, speed, and long life are important.

Mechanical vs. Solid-State Relays: Key Differences

Speed and Switching Time

One of the more significant advantages of solid-state relays is their speed. Since solid-state relays have no mechanical moving parts, they can switch much faster than mechanical relays. This makes them ideal for high-speed automation processes where quick response times are essential. Mechanical relays, on the other hand, typically have slower switching speeds because they rely on physical movement to operate the contacts.

Durability and Lifespan

Mechanical relays are subject to wear and tear because of the physical movement of contacts. Over time, these moving parts can wear out, causing to potential failures and increased maintenance costs. Solid-state relays, however, have no moving parts, which significantly reduces the chances of mechanical failure.

Power Handling Capacity

Power Relays with mechanical components are known for their ability to handle high currents and voltages, making them suitable for large industrial systems, heavy machinery, and electrical power distribution applications. While solid-state relays have made significant advances in handling high power, mechanical relays may still be the preferred choice for excessively high-load environments.

Size and Cost

Solid-state relays are often more compact than mechanical relays, which can be advantageous in applications where space is limited. However, the initial cost of solid-state relays is typically higher than that of mechanical relays. Despite this, the long-term cost savings in terms of maintenance and durability make solid-state relays a cost-effective option in many cases.

Why Choose Wenzhou Jiajie Electric Co., Ltd. for Your Relays?

With over 15 years of experience in manufacturing Power Relays, Wenzhou Jiajie Electric Co., Ltd. is your trusted partner for all types of relays. Our Relay Factory produces both mechanical and solid-state relays that meet the highest industry standards, ensuring that you get the more reliable products for your specific needs.

We understand the diverse demands of different industries, and our team is committed to delivering high-quality Power Relays designed to optimize the performance of your systems. Whether you need a mechanical relay for high-power machinery or a solid-state relay for fast, efficient control, we offer the expertise and experience to help you make the best choice.

Quick Contact

Yueshang Innovation Park, Wengyang Street, Yueqing City, Zhejiang, China

Pages

Stay In Touch

If you have any questions or need help, feel free to contact with our team.