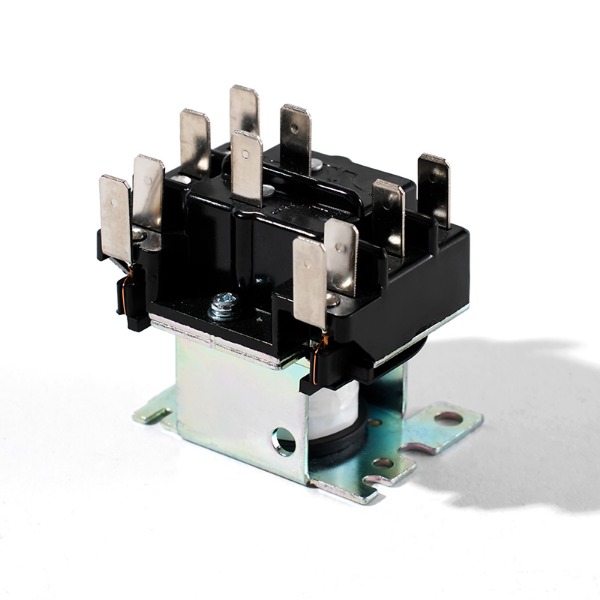

As essential components in various electrical and industrial applications, power relay play a critical role in controlling electrical circuits. However, like any piece of machinery, relays can encounter issues over time. Understanding the common problems that can arise with Power Relays and knowing how to troubleshoot them is key to ensuring smooth and uninterrupted operation. At Wenzhou Jiajie Electric Co., Ltd., our Relay Factory has been at the forefront of producing reliable, high-performance Power Relays for over 15 years. We understand that maintaining these relays is essential to prolonging their lifespan and ensuring ideal performance.

Common Issues with Power Relays

Relay Not Switching (Failure to Activate or Deactivate)

One of the more common issues is a relay failing to either activate (close the contacts) or deactivate (open the contacts) when expected. This can cause systems to malfunction, especially in industrial automation or critical control systems.

Possible Causes:

Coil Failure: The coil that energizes the relay may burn out or fail.

Contact Wear: Over time, the mechanical contacts inside the relay may wear out due to frequent operation.

Improper Voltage: If the voltage applied to the relay is too low or too high, it may prevent the relay from switching.

Solutions:

Check the Power Relay coil for continuity and replace it if damaged.

Inspect the relay contacts for signs of wear or pitting. If the contacts are damaged, the relay should be replaced.

Ensure that the correct voltage is being supplied to the relay. Use a multimeter to verify voltage levels, and make adjustments if necessary.

Relay Contacts Sticking or Welding

Relay contacts can sometimes stick or weld together due to high current, improper voltage, or mechanical wear. This causes the relay to remain in the "on" state, causing to overheating or even potential damage to the connected components.

Possible Causes:

High Power Loads: Relays that handle high current loads can experience arcing between contacts, causing to the contacts welding together.

Incorrect Relay Selection: Using a relay with insufficient power handling capacity for your application can cause to damage.

Solutions:

Ensure that the Power Relay is appropriately rated for the power requirements of the application.

If arcing is an issue, consider adding a snubber circuit to the relay circuit to absorb the electrical surge.

Use a relay with a higher current rating to handle power surges and reduce the risk of contact sticking.

Inconsistent or Weak Switching Performance

If the relay’s switching performance is weak or inconsistent, it can cause to unreliable operation of the connected system.

Possible Causes:

Insufficient Coil Voltage: A low coil voltage may result in insufficient current to close the contacts properly.

Corrosion or Dirt: Dirt, dust, or moisture inside the relay can affect the mechanical movement of the contacts, causing to poor switching performance.

Relay Misalignment: Over time, mechanical relays may suffer from misalignment due to excessive use, causing to erratic switching.

Solutions:

Verify the voltage being supplied to the coil. Ensure it matches the specifications provided by the manufacturer for proper activation.

Clean the relay contacts with appropriate contact cleaners and inspect for corrosion.

Regularly inspect the relay for signs of wear or misalignment and replace parts as needed.

At Wenzhou Jiajie Electric Co., Ltd., we offer high-quality Power Relays that are built to last and perform efficiently. By following regular maintenance practices and using the right relays for your application, you can ensure smooth and reliable operation in your systems. Let our experience and expertise in relay manufacturing help you solve any challenges you face.

Quick Contact

Yueshang Innovation Park, Wengyang Street, Yueqing City, Zhejiang, China

Pages

Stay In Touch

If you have any questions or need help, feel free to contact with our team.