In many control and power systems, DC overload relay or DC power switching relay components are expected to open and close reliably according to control signals. But what happens when a relay remains closed even when its control input is removed — a condition known as “latching” or “sticking”? This behavior can cause unexpected system behavior, extended downtimes, and in some cases, damage to connected loads or power electronics.

A relay is designed so that when its coil is energized, an internal magnetic field pulls contacts together (closing them). When the coil is de‑energized, the magnetic field collapses and the contacts should return to their default state. However, in some cases, the relay remains in the closed position even after the control voltage is removed — this is called latching, and it is not always intentional.

Latching can occur intentionally (in a true latching relay that holds its state without power) or unintentionally, where a standard relay fails to release due to physical or electrical issues.

1. Contact Welding Due to Arcing

One of the main reasons a DC switching relay stays closed is that the contacts have welded together due to arcing. DC arcs are harder to extinguish than AC arcs because DC does not cross zero volts; this makes arcing last longer, heat the contact surfaces, and in extreme cases, fuse them. This welded contact state means the relay remains closed even when the coil is de‑energized.

High inrush currents — especially when switching inductive loads — can exacerbate this problem, causing physical contact deformation or welding over time.

2. Backfeed or Leakage Current

Sometimes the coil of the relay may receive a tiny residual current even when it’s supposed to be off. This leakage or backfeeding can be due to incorrect wiring, shared ground issues, or voltage bleed through other components in the circuit. Even a small amount of current can keep the relay in its energized state long enough to appear “latched.”

Checking your wiring for unintended feedback paths and using proper coil suppression components like diodes can help eliminate this source of unintentional latching.

3. Voltage Bleeding Slowly on DC Supplies

In DC power systems, capacitive elements on the power rails (such as in power supplies or filters) can cause the voltage to fall slowly after power is removed. This slow decay can keep a relay coil energized at a low level for longer than expected, maintaining contact closure. This behavior has been noted in dc ok relay modules where the power supply voltage pals slowly bleed down, keeping the relay engaged even after the system is turned off.

To identify this situation, measure the actual voltage at the relay coil terminals as the system powers down. If the voltage is above a threshold that sustains coil magnetism, consider adding bleeder resistors or redesigning the power‑off behavior.

4. Mechanical Issues or Relay Damage

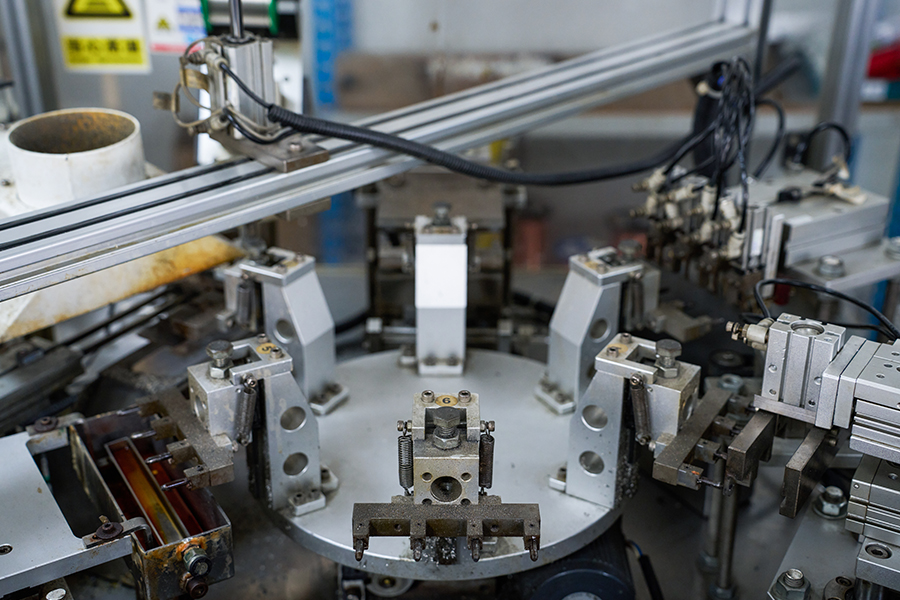

Mechanical wear and tear or contamination inside the relay can also cause sticking. Dirty, pitted, or corroded contacts may no longer separate cleanly when the coil is de‑energized. Environmental factors such as dust, humidity, and vibration can accelerate this problem, particularly in industrial settings.

In these cases, replacing the relay and ensuring appropriate environmental protection (sealed enclosures, periodic maintenance) can help prevent recurrence.

To efficiently troubleshoot why a dc power switching relay remains latched, follow these steps:

Visual Inspection: Look for visible damage or discoloration on contacts and relay surfaces.

Voltage Monitoring: Use a multimeter to observe coil voltage during transition — check for residual voltage that might keep the coil energized.

Check Wiring and Backfeeds: Ensure there are no unintended paths feeding current back into the coil circuitry.

Contact Resistance Measurement: If contacts have welded, resistance will read nearly zero even with coil removed.

Test with Load Removed: Disconnect the load and test the relay in isolation. If it still latches, the issue is likely within the relay itself.

Preventing unintended relay latching in dc overload relay and dc power switching relay applications can improve system reliability:

Select Proper DC‑Rated Parts: Ensure relays are specifically designed for DC switching conditions, with appropriate contact materials and arc suppression features.

Use Protective Components: Flyback diodes, snubbers, and freewheeling circuits help reduce arcing and protect coils from back EMF.

Avoid Overload Conditions: Operating a relay consistently at or near its maximum rating increases wear and the likelihood of welding or sticking.

Regular Maintenance: Replace relays showing signs of wear before they completely fail.

Many industrial designers, including those at Wenzhou Jiajie Electric Co., Ltd., emphasize selecting relays that match the electrical and mechanical demands of the application and incorporating protective measures to avoid unintended latch‑on conditions.

Quick Contact

Yueshang Innovation Park, Wengyang Street, Yueqing City, Zhejiang, China

Pages

Stay In Touch

If you have any questions or need help, feel free to contact with our team.