Relays play a critical role in robotic control systems, providing reliable switching capabilities for various electrical circuits. From industrial automation to small-scale robotics, relays help manage power distribution, protect sensitive components, and enable precise control of motors, sensors, and actuators. Their versatility allows engineers to implement both AC and DC circuits efficiently, ensuring that robotic systems operate smoothly under different load conditions.

AC and DC relays are fundamental components in robotic control systems. An AC relay is designed to handle alternating current circuits and is commonly used for controlling motors, heaters, and other devices powered by AC. On the other hand, a DC relay operates in direct current circuits and is often used for low-voltage control signals or battery-powered robots. Choosing the right type of relay is essential because it directly affects the switching performance and longevity of the robotic system. Proper relay selection also ensures that voltage spikes and electrical noise do not disrupt sensitive components.

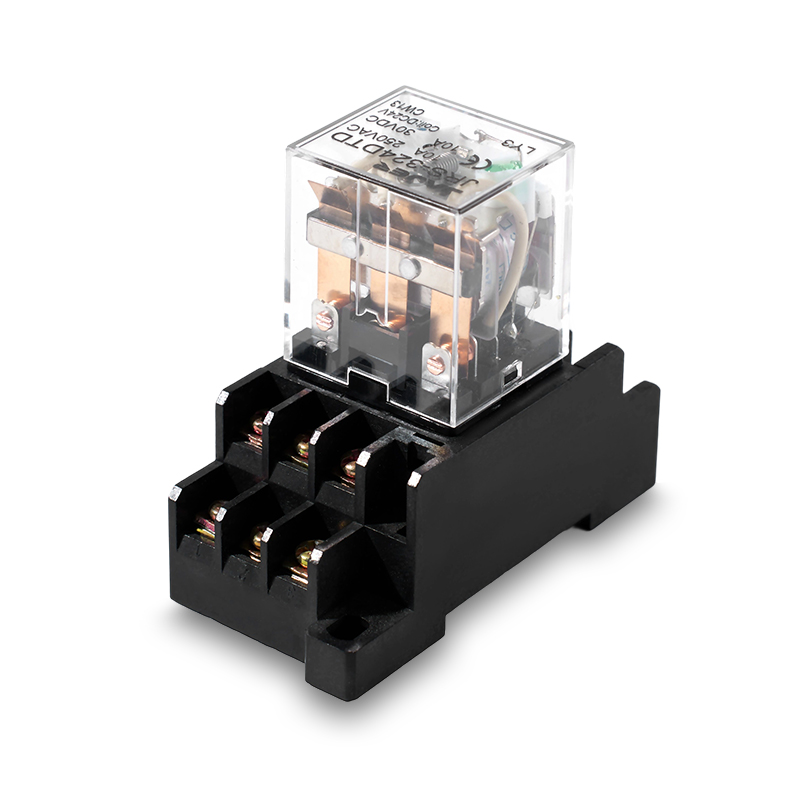

In robotic applications, a heavy-duty relay socket can enhance stability and ease of maintenance. These sockets allow relays to be mounted securely and replaced quickly without rewiring. This feature is particularly useful in industrial robots, where frequent maintenance or component replacement may be required. Heavy-duty sockets are built to handle high current loads and provide strong electrical connections, reducing the risk of overheating or contact failure. For engineers designing robotic systems, incorporating robust relay sockets contributes to both safety and operational reliability.

One of the more common uses of relays in robotic systems is motor control. Robots rely on electric motors to perform tasks such as moving arms, rotating wheels, or operating conveyor belts. Relays act as switches that can turn motors on or off in response to control signals from a microcontroller or programmable logic controller (PLC). Using relays allows designers to separate the low-power control circuit from the high-power motor circuit, which protects sensitive electronics from voltage fluctuations and current surges.

Robotic systems often include a variety of sensors, including proximity sensors, pressure sensors, and limit switches. Relays help integrate these sensors into the control logic, allowing the robot to respond automatically to changing conditions. For example, when a proximity sensor detects an object, a relay can trigger a motor to stop or reverse direction. This approach ensures precise movement and prevents collisions or damage to the robot and its environment. Both AC and DC relays can be used depending on the voltage requirements of the sensor and control system.

Safety is a significant concern in robotic control systems, particularly in industrial settings. Relays provide electrical isolation between control circuits and high-power devices, reducing the risk of short circuits or electrical shock. Heavy-duty relay sockets further enhance safety by maintaining a secure connection even in environments with vibrations or mechanical stress. Engineers often design systems with redundant relays to ensure that a single relay failure does not disrupt the entire operation, maintaining consistent and safe performance.

Beyond controlling motors, relays are also used in robotic systems for lighting, heating, and communication functions. For instance, a robot performing inspection tasks might use relays to power auxiliary lights or cameras when needed. Relays can also switch power between different subsystems depending on operational requirements. Their ability to handle both AC and DC loads makes them versatile for a wide range of robotic applications.

Regular maintenance is essential for keeping relays in robotic systems functioning correctly. Heavy-duty relay sockets make inspection and replacement straightforward, less downtime. Ensuring that relays are rated correctly for voltage and current, and that connections are secure, helps extend the life of the system. By monitoring relay performance and replacing components as needed, engineers can maintain consistent robotic operation and reduce unexpected failures.

Relays are indispensable components in robotic control systems, providing reliable switching, safety isolation, and flexible integration for both AC and DC circuits. Using heavy-duty relay sockets enhances stability and simplifies maintenance, while careful selection and application of relays improve the performance and longevity of robots. Whether for motor control, sensor integration, or auxiliary functions, relays remain a key technology in ensuring that modern robotic systems operate efficiently and safely.

Quick Contact

Yueshang Innovation Park, Wengyang Street, Yueqing City, Zhejiang, China

Pages

Stay In Touch

If you have any questions or need help, feel free to contact with our team.