General purpose relay and industrial control relay are essential parts of electrical and industrial automation systems that guarantee the efficient operation of numerous devices. Both of these relays serve similar purposes in controlling electrical circuits, but their specific applications, features, and performance characteristics differ.

What is a General Purpose Relay?

A General Purpose Relay is an electromechanical switch designed to control various low- to medium-power circuits. They are commonly used in devices like home appliances, small motors, and light control systems. The primary role of a general purpose relay is to control the power supply to these devices, making them easier to automate. General Purpose Relays are flexible, widely available, and often used in applications where performance, reliability, and affordability are key concerns.

One of the main advantages of general purpose relays is their versatility. These relays can handle a variety of loads and are suitable for use in many different systems. They are often used in applications that do not require extremely high switching capacity or precision, such as household devices, office equipment, or even electric toys.

What is an Industrial Control Relay?

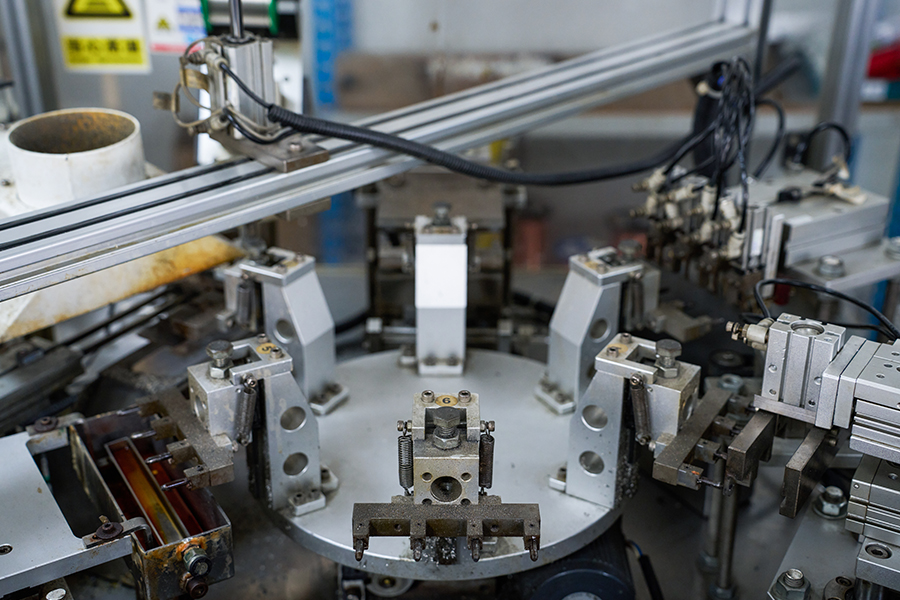

Industrial Control Relays, on the other hand, are a class of relays designed specifically for industrial applications. These relays are built to withstand the harsh conditions of factory floors, heavy machinery, and automation control systems. Unlike general purpose relays, industrial control relays are engineered to handle high voltages and currents, and they often come with enhanced features like higher switching speeds, reliability in extreme conditions, and more robust construction.

An Industrial Control Relay is typically used in large-scale automation systems, such as those found in factories, power plants, and heavy machinery. These systems require relays that can manage high loads, multiple inputs, and outputs, and can work in environments that may include extreme temperatures, vibrations, and electrical noise.

Now that we understand the basic functions of both General Purpose Relays and Industrial Control Relays, let’s explore their key differences:

1. Applications

General Purpose Relays are used in a wide variety of applications, such as household appliances, simple automation tasks, and control systems where reliability and cost-effectiveness are prioritized.

Industrial Control Relays are used in industries like manufacturing, robotics, energy, and large-scale automation systems where high capacity, durability, and precise control are crucial.

2. Load Handling Capacity

General purpose relays are designed for lower load capacities and are suitable for devices that don’t require high power.

Industrial control relays, however, are specifically built to handle higher loads and more demanding environments. They can manage larger industrial equipment like motors, conveyors, and large electrical panels.

3. Durability and Reliability

While general purpose relays are reliable, they are not built to endure the harsh conditions often found in industrial settings.

Industrial control relays, on the other hand, are designed for robustness, able to withstand extreme temperatures, vibrations, and electrical disturbances.

4. Size and Complexity

General purpose relays tend to be more compact and simpler in design, making them more affordable and easier to integrate into a variety of devices.

Industrial control relays are often larger and more complex, offering features like multiple contacts, higher switching speeds, and the ability to handle multiple inputs and outputs simultaneously.

Choosing the right relay not only ensures the smooth operation of your electrical system but also enhances the longevity and safety of your equipment. To make the right choice, always assess the specific needs of your system and the performance requirements before making a selection.

Quick Contact

Yueshang Innovation Park, Wengyang Street, Yueqing City, Zhejiang, China

Pages

Stay In Touch

If you have any questions or need help, feel free to contact with our team.