Relays play a vital role in ensuring the safety and reliability of critical equipment. These devices are designed to control electrical circuits by opening or closing contacts in response to a signal. In many industries, ranging from HVAC systems to industrial machinery, relays help prevent damage to sensitive equipment and reduce the risk of electrical hazards. Choosing the right type of relay and understanding its safety features can significantly improve operational reliability.

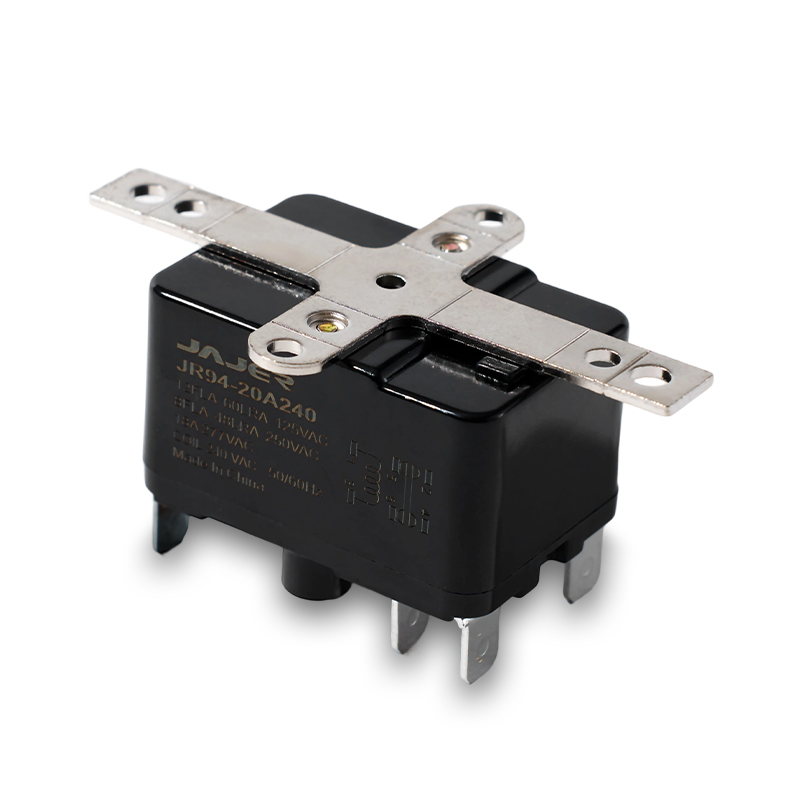

PCB power relays are compact components designed to be mounted directly onto printed circuit boards. They are widely used in applications where space is limited but reliable switching is required. One of the key safety features of PCB power relays is their electrical isolation. The relay separates the low-voltage control circuit from the high-power output circuit, reducing the risk of electrical shock or equipment damage.

Another safety aspect of PCB power relays is their ability to handle high inrush currents. In critical equipment, sudden surges can occur when motors or capacitors start up. A PCB power relay can endure these surges without damage, ensuring continuous protection for the equipment it controls. Additionally, these relays often include arc suppression features, which less the risk of contact wear or electrical fires caused by sparks.

In HVAC systems, 24V relays are commonly used to control compressors, fans, and other components. These relays ensure that each part of the system operates safely according to the control signals from thermoreats or building management systems. A key safety feature of a 24V HVAC relay is its low-voltage operation, which reduces the risk of electrical hazards for service technicians and operators.

Thermal protection is another important aspect of 24V HVAC relays. Many relays include internal mechanisms to prevent overheating if the load exceeds rated limits. This feature is particularly important in heating and cooling systems where continuous operation could otherwise advance to component failure or fire hazards. The relay also provides reliable isolation between control circuits and high-power loads, ensuring that faults in one part of the system do not propagate to other areas.

Safety in critical equipment often relies on fail-safe relay designs. Many modern relays are configured so that if power is lost, the contacts default to a safe position. For example, normally closed contacts may open to disconnect a circuit in case of a control signal failure, preventing unexpected operation. This feature is crucial in industrial machinery, medical equipment, and HVAC systems, where uncontrolled operation could cause injury or equipment damage.

Another safety measure is contact protection. Relays with silver alloy contacts or other wear-resistant materials ensure consistent performance over thousands of switching cycles. This reduces the likelihood of contact degradation that could advance to overheating, arcing, or failure. For applications where switching speed and reliability are critical, these features provide additional security.

Regular monitoring and maintenance can further enhance relay safety. Visual inspection for discoloration, mechanical testing of contact operation, and verifying coil resistance can prevent unexpected failures. In automated systems, diagnostic features in modern relays can alert operators to potential issues before they become critical.

Using relays like PCB power relays and 24V HVAC relays in combination with appropriate fuses, circuit breakers, or surge protectors can also improve overall system safety. Proper installation, alignment with manufacturer specifications, and ensuring that relay ratings match the application load are essential steps in maintaining a safe operation.

Relays are key components in maintaining the safety of critical equipment across various industries. PCB power relays provide reliable electrical isolation and inrush current handling, while 24V HVAC relays ensure safe operation in heating and cooling systems. With fail-safe designs, durable contacts, and proper monitoring, relays contribute significantly to equipment protection and operational reliability. By understanding these safety features and incorporating them thoughtfully into system design, engineers and technicians can reduce risks and maintain stable, secure operations.

Quick Contact

Yueshang Innovation Park, Wengyang Street, Yueqing City, Zhejiang, China

Pages

Stay In Touch

If you have any questions or need help, feel free to contact with our team.