In the modern industrial environment, the reliability and durability of relays play a critical role in maintaining smooth operations. Heavy-duty machinery often operates under bad conditions, including high temperatures, vibrations, and frequent load switching. Selecting relays that can withstand these challenges is essential for less downtime and ensuring continuous production.

Durability in relays refers to their ability to function effectively over extended periods despite challenging operational conditions. For industrial machinery, relays must resist mechanical wear, electrical stress, and environmental factors. High power solid state relays (SSRs) have become increasingly popular in this context due to their enhanced durability and ability to handle significant electrical loads without mechanical contact. Unlike electromechanical relays, SSRs reduce wear and tear, offering consistent performance even under frequent switching.

High power solid state relays are widely used in heavy-duty industrial equipment such as motor control systems, heating elements, and large conveyor systems. Their robust construction allows them to handle high current and voltage levels safely. Additionally, SSRs provide silent operation, reducing noise in environments where machinery runs continuously. Their compact design and small maintenance requirements make them suitable for installations where mechanical relays may be prone to failure due to vibration or repeated cycling.

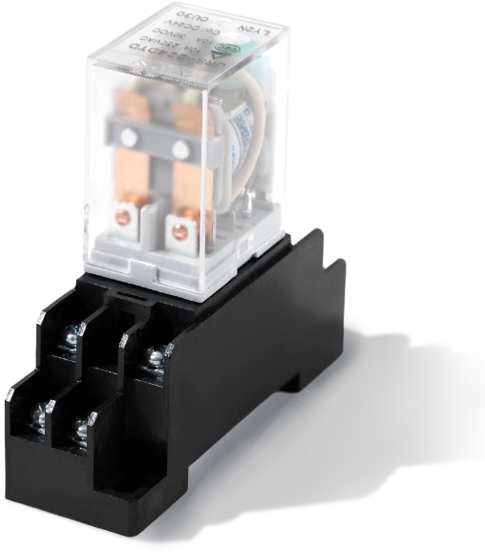

Another type of relay commonly used in demanding industrial applications is the double signal relay. This relay provides dual output signals for monitoring and control, offering additional flexibility in complex systems. In heavy-duty machinery, double signal relays can enhance safety by providing redundancy, allowing operators to detect faults or abnormal conditions quickly. These relays are particularly useful in systems requiring synchronized control, where multiple signals must be managed simultaneously without compromising operational integrity.

Heavy-duty machinery often operates in environments with dust, moisture, or chemical exposure. Relays used in these settings must resist corrosion and maintain electrical performance despite such conditions. High power solid state relays are typically sealed to protect against environmental factors, while electromechanical double signal relays may include protective housings or coatings. Ensuring that relays are rated for industrial environmental standards can significantly improve their lifespan and reduce maintenance needs.

Heat generation is another critical factor affecting relay durability. Heavy-duty machinery often involves continuous high-current operations that produce significant heat. High power solid state relays have lower heat generation compared to mechanical relays and can include built-in heat sinks or external cooling solutions. Proper thermal management prevents overheating, reduces stress on internal components, and maintains stable relay performance over time. For double signal relays, adequate spacing and ventilation in relay panels are essential to avoid heat accumulation that could affect switching accuracy and reliability.

While solid state relays require small maintenance, double signal relays still benefit from periodic inspections to ensure contacts remain functional and connections are secure. Monitoring relay performance in real-time can help identify early signs of wear, overheating, or electrical anomalies. In heavy-duty industrial machinery, integrating relay monitoring into the control system enables predictive maintenance, helping to avoid unexpected downtime and extend the overall service life of the equipment.

Relay durability is a key factor in the efficiency and safety of heavy-duty industrial machinery. Both high power solid state relays and double signal relays offer unique advantages, supporting reliable operation under demanding conditions. Understanding the specific requirements of each application, including environmental challenges, thermal management, and control complexity, ensures that the chosen relay provides consistent performance over time. By focusing on durable relay solutions, industrial operators can maintain steady production, reduce maintenance needs, and safeguard the longevity of their equipment.

Quick Contact

Yueshang Innovation Park, Wengyang Street, Yueqing City, Zhejiang, China

Pages

Stay In Touch

If you have any questions or need help, feel free to contact with our team.